IceWhale’s ZimaCube NAS has been the center of attention since its debut on Kickstarter.

This exquisite and compact “Cube” NAS has captured the hearts of numerous tech enthusiasts with its elegant design, powerful features, and IceWhale’s consistent dedication to craftsmanship. However, as the first batch of crowdfunded units reached users, a challenge emerged - the ZimaCube’s thermal management system seemed like an open question posed by IceWhale, becoming a hot topic within the user community.

Having received my ZimaCube earlier than overseas users, I quickly identified this issue and conducted a thorough analysis and modification.

The CPU’s High-Temperature Trial

The upper compartment of the ZimaCube primarily houses the motherboard, with the CPU serving as the driving force behind this “digital cube.” However, when users eagerly unleashed the CPU’s performance, its cooling system revealed its limitations. Despite the stock turbo cooler diligently operating at full speed, heat seemed trapped around the CPU, unable to dissipate effectively. CPU temperatures consistently remained high under heavy loads, even reaching an alarming 100°C. To combat this “heat wave,” the turbo fan had to run at full blast, resulting in an unwelcome “roar” for users.

The root cause lies in some questionable design and material choices in the ZimaCube’s thermal management system:

-

Protection Cover: Imperfect Material and Manufacturing The first step in CPU cooling is transferring heat to the heatsink. However, the ZimaCube’s original protection cover uses aluminum alloy, which has inferior thermal conductivity compared to copper (aluminum’s thermal conductivity is approximately half that of copper). In addition, the sandblasted surface treatment creates a rough texture that further impedes heat transfer, acting like an “insulation layer” for the CPU.

-

Heatsink Installation: Details Matter The initial batch of ZimaCube units also suffered from heatsink installation flaws. The horizontal mounting method put pressure on nearby capacitors, and the heatsink base didn’t make full contact with the protection cover, resulting in uneven thermal paste application and impacting cooling efficiency.

-

Active Cooling: A Missing Link While the ZimaCube’s upper compartment has ventilation holes, it lacks an active airflow design. This means the heat generated inside can only passively escape through the small openings, ultimately accumulating within the confined space and creating an undesirable “oven effect.”

My Optimization Solution: Resolving the CPU’s High-Temperature Crisis

Faced with the ZimaCube’s upper compartment thermal challenges, users have brainstormed and actively explored optimization solutions. Here are the modifications I implemented:

-

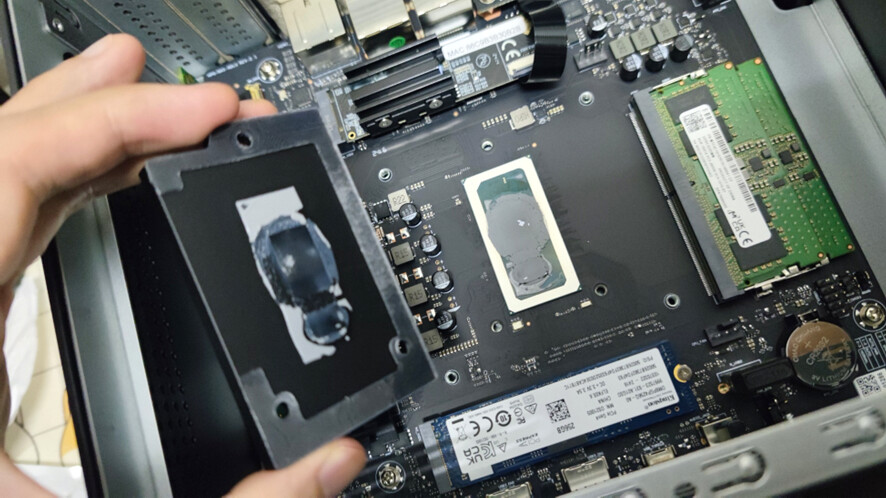

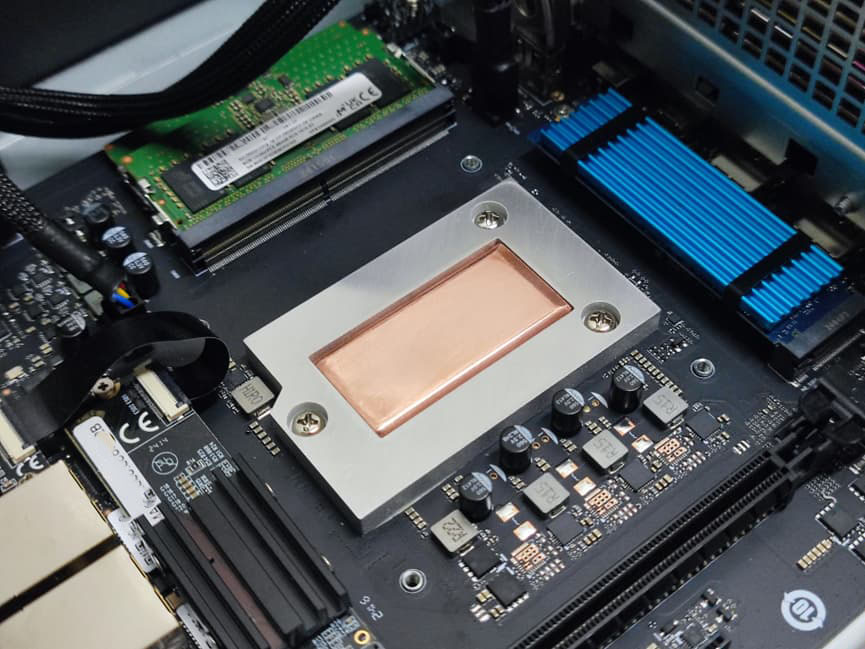

High Thermal Conductivity Pad Replacement: I designed and manufactured a replacement part for the original protection cover using CNC-machined aluminum for the frame and embedded a T2 pure copper block in the center to maximize heat transfer efficiency, creating a “fast lane” for CPU heat dissipation.

-

Upgraded Tower Heatsink: The original cooler was replaced with a 2U server-grade tower heatsink, striking a balance between size and cooling capacity, effectively eliminating the CPU overheating issue.

-

Implementing Active Cooling: A 4cm fan was installed at the front ventilation grille to force air exchange between the inside and outside, efficiently expelling heat from the ZimaCube’s confined space.

-

Optimized Heatsink Installation: The heatsink was reinstalled, ensuring full contact with both the CPU and the protection cover. High-quality thermal paste was used to fill any gaps and eliminate “hot spots.”

The Hard Drive Noise Dilemma

Compared to the “high-temperature” predicament in the upper compartment, the ZimaCube’s lower compartment, housing the hard drives, faces a different challenge - noise. The two PWM fans responsible for hard drive cooling seem to run relentlessly at high speeds, even when the system is under low load, adding an unwelcome “hum” to an otherwise quiet environment.

The root causes of the ZimaCube’s hard drive noise issue can be attributed to the following:

-

Fan Control Strategy: Overly Aggressive “Diligence” The ZimaCube’s PWM fan control strategy appears overly conservative, maintaining high fan speeds even when hard drive temperatures are low, resulting in unnecessary noise.

-

Airflow Design: An Obstacle Course The design of the ZimaCube’s fan exhaust also leaves room for improvement. The presence of the NAS backplane and protective mesh acts as a series of barriers in front of the fans, obstructing airflow and contributing to noise generation.

Optimization Solutions: Restoring Tranquility to the Hard Drive Bay

To mitigate the ZimaCube’s hard drive noise, users have actively experimented with and proposed several viable solutions:

-

My Solution: Leveraging the SYS_FAN Header By connecting the motherboard’s SYS_FAN header to the rear fan, I successfully gained control over fan speeds. This cost-effective solution allows for fine-tuning fan curves through the motherboard BIOS. However, it lacks direct hard drive temperature monitoring, requiring users to rely on experience for optimal settings.

-

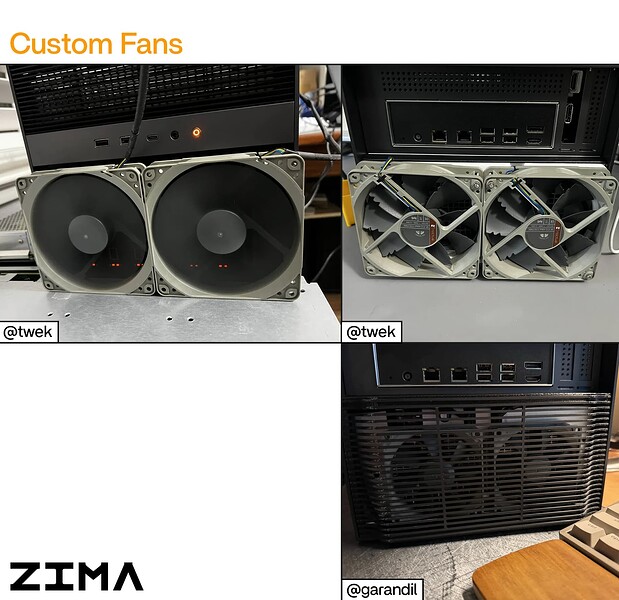

Other User Solutions: Some resourceful users have replaced the stock hard drive fans with quieter alternatives, using 3D printing to create custom rear covers compatible with thicker, quieter fans, further reducing noise levels.

-

My Suggestions for Official Optimization: Smarter Fan Control and Improved Airflow Design Users hope that IceWhale will implement optimized fan control strategies in future product iterations, such as dynamically adjusting fan speeds based on hard drive temperatures to minimize noise while maintaining effective cooling. Additionally, enlarging the mesh openings and optimizing airflow pathways can further improve cooling efficiency, addressing the root cause of fan noise.

ZimaCube Thermal Optimization: A Testament to Collective Wisdom

The ZimaCube’s exceptional hardware is undeniable. While its thermal system might not be perfect, it represents a unique opportunity for “tweaking” – a testament to IceWhale’s pursuit of both ultimate performance and a compact design. This presents a chance for both enthusiastic users and the dedicated IceWhale team to collaborate, explore, and ultimately perfect this remarkable device.

Fortunately, the ZimaCube benefits from a vibrant and innovative user community. Users have proactively shared their experiences, brainstormed solutions, and explored various optimization approaches, transforming this “trial by fire” into a testament to collective wisdom.

With the combined efforts of both users and IceWhale, we are confident that the ZimaCube’s thermal challenges will be overcome, allowing this eagerly anticipated “digital cube” to continue its legacy in an even more refined form.